Detailed Photos

Performance

1. Main body frame: apply high-duty structural steel and Special welding technic, its outstanding steadiness will guarantee the equipment’s rigidity and seismic resistance.

2. Guidepost: apply with super special steel, chromeplated surface will give good torsion resistance and wear-resisting performance, plus Four rod guide mode and over-length type guide bearing, which guarantees the accurate move of indenter and molds; moving parts apply special device, in order to easy lubricate and not easy wear.

3. Color system: The color device crane apply hydraulic system control, by connection of rubber spring and crane the color device and hopper vibrating will be damped, in the meantime, it can prevent the left color concreted, discharge gate control the hopper, in order to achieve evenly color distributing.

4. Distribution system: apply design of material storage and material separate dividing tech. material box feeding can be precisely controlled, under the effect of enforcing broken arch machine, which generate strong centrifugal discharging force, to make material distributing fast and even.

5. Vibration system: Separate coupling vibration technology is used to expand the effective vibration area by 2 times, which greatly improve the quality and output of the production, and effectively extend the life of the mold; The vibration box adopts a suspended structure and can withstand severe vibration without damage. And the vibrating shaft adopts the eccentric synchronous rotation structure to generate the excitation force in the vertical direction, which can optimize the fabric and the forming effect.

6.PLC control system: set the technical parameters such as flow and pressure of each action through the touch screen to achieve ideal man-machine dialogue. The control system consists of three control units: batch mixing automatic program control system, molding host, transport board machine, lift-unload automatic program control system and weight control system. The electrical components of this system are all imported brand products, such as Mitsubishi, Omron, Siemens, etc, thus ensure reliable performance and low failure rate.

7. Multi-purpose of one machine: By replacing the mold, it can produce cement products with different specifications of porous bricks, hollow blocks, roadside stones, pavement bricks, grass bricks and slope protection bricks. The fabric device can produce products such as colorful pavers.

Specification

1. QT4-15 Automatic block forming machine Main technical parameters:

| Dimension Of block making machine | 3600×1800×2600mm | Motor Power | 29.4KW |

| Mould Area | 550×900mm | Vibration Force | 40KN |

| Working cycle | 15-18S | Concrete mixer model | JS500 |

| The Size Of The Pallet | 900×550×30mm | Weight Of The block making machine | 6000kgs |

2. QT4-15 Automatic block forming machine Production capacity:

| Size(LxWxH) | Pcs/Mould | Pcs/ Hr | Pcs/ 8 Hr |

| 400X100X200 | 8 | 1200-1920 | 9600-15360 |

| 400X150X200 | 6 | 900-1440 | 7200-11520 |

| 400X200X200 | 4 | 600-960 | 4800-7680 |

| 400X250X200 | 3 | 450-720 | 3600-5760 |

| 200X100X60 | 16 | 1920 | 15360 |

| 200X163X60 | 8 | 1200 | 9600 |

| We can provide different sizes mould as you request. | |||

3. How does Automatic Block Making Machine work?

1. Cement silo and screw conveyor: The cement silo is used to store the bulk cement which is used for concrete. The screw conveyor is connect with the cement silo and concrete mixer to transfer the cement into the concrete mixer. These two parts are optional parts. You can get them at local market or purchase them from us together with our block making machine;

2. Aggregate batching machine: It consists of two or three storage bins and one weighing bin. It also contains belt conveyers which is used to convey aggregate and sand from the storage bins to weighing bin. Batching and weighing is controlled by PLC.

3. Concrete Mixer: All the ingredients are mixed in this concrete mixer. Mixing time and speed is controlled by PLC. The water pump which is controlled by time relay adds water to the mixer automatically;

4. Belt conveyor: after the concrete is ready, it will be discharged to this belt conveyor, the belt conveyor will transfer the concrete to the concrete block machine;

5. Block making machine: This is key part of the production line. It presses the concrete to block. It can be used to make various hollow block, solid brick, paver brick and kerbstone by changing different sizes moulds;

6. Stacker: Stacker is used to stack the blocks automatically, which is high-efficient and labor saving.

7. After the above procedures, the blocks will be transported to the storage yard for drying.

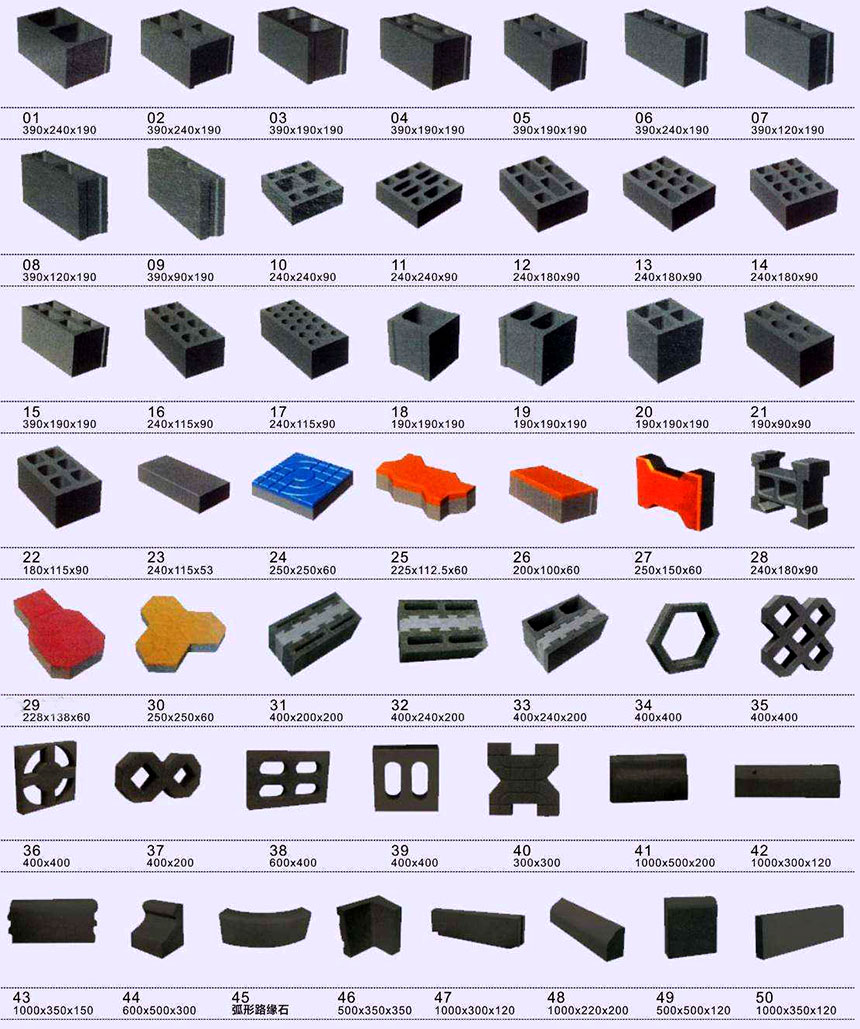

4. Block and Brick Models:

Tags: china block making machine concrete brick making machine price simple brick making machine concrete hollow block making machine concrete mixer machine with lift price ready mix concrete plants for sale ready mixed concrete mixing plant concrete mixture machine

Solutions

Block Making Machine

QT8-15 Automatic Block Making Plant

QT4-15 Automatic Block Making Plant

QT6-15 Automatic Block Making Plant

QT8-15 Automatic Block Making Plant

QT10-15 Automatic Block Making Plant

QT4-20 Block Making Machine

QT5-20 Block Making Machine

Products

Concrete Mixers

Concrete Batching Plant

Concrete Conveying Plant

- Truck Mounted Concrete Pump

- Elevator shaft Self-climbing Concrete Placing Boom

- Mobile Hydraulic Concrete Placing Boom

- Floor climbing Hydraulic Concrete Placing Boom

- Concrete Transit Mixer on Truck

- XBS/DXBS Fine Stone Concrete Pump

- Concrete Mixer Truck

- 6cbm Concrete Truck Mixer

- Manual Concrete Placing Boom

- 8cbm Concrete Truck Mixer

Related Concrete Equipment

Concrete Block Making Plant

NEWS

- DHBT15 Diesel Engine Concrete Mixer with Pump was delivered to North America

- Hamac 35m3 concrete batching plant delivering to the African customer

- Hamac HMC150 self loading concrete mixer delivering to the Middle East

- 2 units of 10 m3 transit mixer trucks are delivered to South Africa

- TWO UNITS OF HGY15 CONCRETE PLACING BOOM WAS DELIVERED TO EUROPE

- 4 Units of bolted type cement silos were delivered to South East Asia

- Reliable Performance of HZS120 Concrete Batching Plant

- Low Price Small Size Concrete Pump for Saudi Arabia

- An Independent Off-road Mobile Batching Plant

Get Quote

Get Quote Chat Online

Chat Online